In the realm of thermal management, phase change materials (PCMs) have emerged as a revolutionary solution, offering unparalleled efficiency in heat absorption and dissipation. These materials leverage their latent heat capacity to regulate temperature, making them indispensable in industries ranging from electronics to construction. At the heart of their performance lies a critical property: thermal conductivity. Unlike traditional cooling methods, PCMs rely on their ability to rapidly transfer heat during phase transitions, ensuring optimal thermal regulation without external energy input.

The thermal conductivity of PCMs dictates how effectively they can absorb and redistribute heat. Materials with high thermal conductivity, such as metallic alloys or graphite-enhanced composites, facilitate swift heat transfer, making them ideal for applications requiring rapid cooling. Conversely, organic PCMs like paraffin waxes exhibit lower conductivity but excel in scenarios where gradual heat release is preferred. This duality underscores the importance of selecting the right PCM based on specific thermal demands.

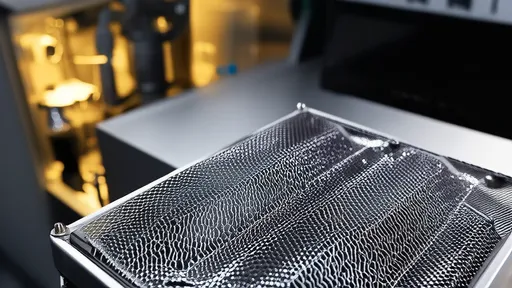

Recent advancements in material science have focused on enhancing the thermal conductivity of PCMs without compromising their phase change properties. Researchers have explored various techniques, including nanoparticle doping and hybrid composites, to achieve this balance. For instance, embedding carbon nanotubes or graphene into paraffin matrices has shown remarkable improvements in heat transfer rates. These innovations are particularly relevant in electronics, where overheating can lead to performance degradation or even failure.

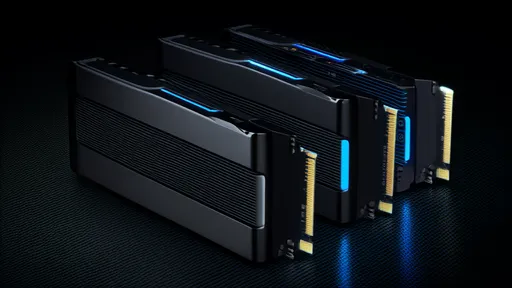

The integration of high-conductivity PCMs in electronic devices has transformed thermal management strategies. Modern smartphones, laptops, and servers now incorporate PCM-based heat sinks to mitigate thermal throttling. By absorbing excess heat during peak loads and releasing it gradually, these materials ensure consistent performance and longevity. Moreover, their passive operation eliminates the need for noisy fans or bulky cooling systems, paving the way for sleeker, more efficient designs.

Beyond electronics, PCMs are making waves in renewable energy systems. Solar thermal plants, for example, utilize these materials to store excess heat during the day and release it at night, ensuring continuous energy output. The thermal conductivity of the PCM plays a pivotal role here, as it determines how quickly the stored energy can be retrieved. Similarly, in building insulation, PCM-enhanced walls and roofs leverage their thermal properties to maintain indoor comfort, reducing reliance on HVAC systems.

The automotive industry is another sector benefiting from high-conductivity PCMs. Electric vehicles (EVs) employ these materials to manage battery temperatures, enhancing both safety and efficiency. By maintaining optimal operating conditions, PCMs help extend battery life and improve overall performance. This application is particularly critical as the demand for EVs continues to surge, driving innovation in thermal management solutions.

Despite their advantages, challenges remain in the widespread adoption of PCMs. Cost and scalability are significant barriers, especially for advanced composites with enhanced thermal conductivity. Additionally, ensuring long-term stability and reliability under cyclic thermal loads is an ongoing area of research. Addressing these hurdles will be crucial for unlocking the full potential of PCMs across diverse industries.

Looking ahead, the future of phase change materials appears promising. As research progresses, we can expect even more efficient and cost-effective solutions to emerge. The continuous refinement of thermal conductivity properties will undoubtedly expand their applications, solidifying PCMs as a cornerstone of modern thermal management. Whether in consumer electronics, renewable energy, or transportation, these materials are set to play an increasingly vital role in our technologically driven world.

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025

By /Aug 15, 2025